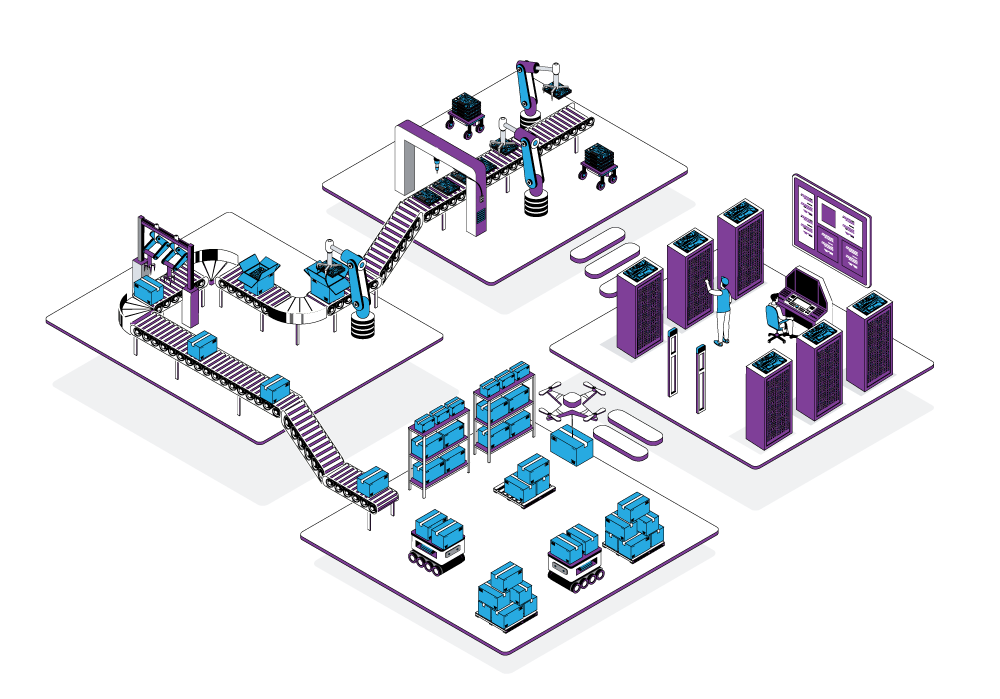

Production Line Setup Services

Granulation & Compounding Lines

Advanced pelletizing systems for plastic recycling, masterbatch, biodegradable compounds, and high-performance polymers

Production Line Setup

Granulation & Compounding Lines

Our granulation and compounding lines are designed to serve both sustainability-focused recyclers and high-value compounders. These systems enable efficient reprocessing of plastic waste and precise formulation of customized plastic materials such as filler masterbatch, color masterbatch, biodegradable resins, and engineering polymers.

Applications

Plastic Recycling & Regranulation

Post-consumer LDPE, LLDPE, HDPE film recycling

Rigid plastic reprocessing (PET, PP, ABS, PS)

Industrial scrap recovery and inline waste recycling

Masterbatch Production

White, black, color masterbatch

Filler masterbatch (CaCO₃, talc, TiO₂-based)

Additive masterbatch: UV stabilizers, antioxidants, antistats

Biodegradable Compounding

PLA, PBAT, PBS compounds

PLA + starch blends

Water-soluble or compostable granules for film blowing and extrusion

Engineering Plastics & Custom Compounds

Glass fiber reinforced PP/PA/PC

Flame retardant, impact-modified polymers

High-performance blends with functional additives

Supported Materials

PE, PP, PS, PET, ABS, PLA, PBAT, PA, PC, POM

Filler blends (CaCO₃, talc)

Recycled pellets & flakes

Fiber-loaded and mineral-filled materials

Organic/biodegradable starch-based blends

Plentiful Choices

Key System Features

Extrusion Configuration

- Twin-screw extruders (co-rotating parallel or conical) for compounding

- Single-screw extruders for general recycling and low-shear processing

- L/D ratios: 28:1 – 52:1 for different process intensities

Feeding & Dosing

- Main hopper with forced feeding system for light bulk density materials

- Side feeders for fillers, fibers, powders

- Liquid/paste dosing pumps for additives and modifiers

Degassing & Filtration

- One or two vacuum vents for moisture and volatile removal

- Melt filtration systems: manual or automatic screen changers

- Melt pressure sensors and backflush systems

Pelletizing Options

- Strand pelletizing for compounds and rigid polymers

- Water-ring pelletizing for films and flexible resins

- Underwater pelletizing for high-output or sticky materials

Post-Processing

- Vibrating classifier, dewatering units, silo storage

- Integrated inline recycling loops

- Cooling systems: water bath, air knife, centrifuge dryer

Technical Specifications

Typical Range

Feature

Specification Range

Output Capacity

100 – 1500 kg/h

Pellet Size

1.5 – 4 mm (adjustable)

Moisture Sensitivity

Suitable for PLA, PBAT, PET

Additive Accuracy

±0.3% with gravimetric dosing

Power Consumption

Optimized for energy efficiency

Industries Served

Plastic recycling & waste management

Flexible packaging and film producers

Masterbatch and additive producers

Biodegradable packaging manufacturers

Engineering plastics & automotive supply chains

Agricultural plastics and sustainability programs