| Specification | Details |

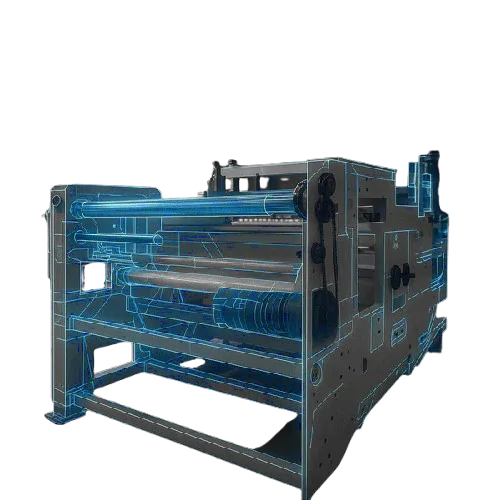

| Machine Type | Roll-to-Roll Paper Slitting Machine |

| Model | GW-FQ-1600A |

| Application | Slitting large paper rolls into smaller rolls |

| Compatible Materials | Standard paper, stone paper, synthetic paper |

| Unwinding Unit | Included |

| Rewinding Unit | Included |

| Maximum Unwinding Width | 1100 mm / 1400 mm / 1600 mm (configurable) |

| Maximum Unwinding Roll Diameter | 1400 mm |

| Minimum Slit Width | 30 mm |

| Maximum Rewinding Roll Diameter | 1400 mm |

| Slitting Speed | Up to 300 meters/min |

| Feeding System | Pneumatic with Air Shaft |

| Edge Trim Removal | Automatic |

| Irregular Roll Slitting Capability | Supported (with auto-sensor paper alignment adjustment) |

| Body Material | Steel and Stainless Steel |

| Delivery Time | 90 days |

| Software & Control Interface | PLC with HMI touchscreen |

| Power Consumption | 23 kW |

| Approximate Machine Weight | 4 tons |

| Approximate Dimensions (L × W × H) | 1.9 × 3.5 × 3.5 meters (varies depending on model) |

Need a Custom Solution?

Get Your One-on-One Consultation

Struggling to find the perfect machine that fits your unique factory layout or production goal?

Precision Cutting for Coated, Waxed, Siliconized & Specialty Papers

The roll-to-roll slitting machine is an advanced solution for accurately cutting jumbo paper rolls into narrower widths across a wide range of substrates, including wax-coated paper, siliconized release liners, PE-coated paper, synthetic paper, kraft, and printing-grade paper. Designed for high efficiency, the machine features automatic edge alignment sensors, web tension control, and automated metering with alarm triggers, ensuring clean cuts even on misaligned or telescoped rolls.

With configurations available for various widths and materials, the machine supports razor, rotary, crush, or dual-knife slitting systems, tailored to thickness and coating types. It guarantees fast, dust-free cutting with high edge quality — making it ideal for label production, packaging, hygiene paper, laminated materials, and specialty industrial applications.

Unleash Precision and Efficiency in Your Paper Conversion

Our state-of-the-art Roll-to-Roll Slitting Machine is engineered to deliver unparalleled precision and productivity for all your paper converting needs. Designed to handle a comprehensive range of paper materials—from delicate tissue paper to heavy-duty kraft and cardboard—this machine transforms wide parent rolls into perfectly slit, high-quality finished rolls with exceptional accuracy and speed.

Whether you’re in the packaging, printing, or specialty paper industry, our slitting machine is the definitive solution to streamline your workflow, minimize waste, and meet the growing demands of your business.

Key Features & Benefits:

- Universal Material Compatibility: Effortlessly slit various paper types, including thermal paper, art paper, kraft paper, coated paper, cardboard, and more.

- Superior Precision: Equipped with advanced sensor and tension control systems to ensure clean, precise cuts with a minimum slitting width as low as 20mm. This guarantees flawless output and reduces material waste.

- High-Speed Operation: Maximize your throughput with a high-speed rewinding system that significantly shortens production cycles and boosts your overall efficiency.

- User-Friendly Interface: The intuitive HMI (Human-Machine Interface) touch screen allows operators to easily set parameters, monitor production, and make real-time adjustments, reducing the need for extensive training.

- Robust & Durable Construction: Built with a heavy-duty steel frame, our machine is designed for continuous, high-volume production, ensuring long-term reliability and minimal maintenance.

- Advanced Safety Features: Integrated safety measures, including emergency stop buttons and protective covers, ensure a secure working environment for all operators.

Invest in a machine that grows with your business. Contact us today to learn how our Roll-to-Roll Slitting Machine can revolutionize your production process.