| Specification | Details |

| Model | TC-PRO |

| Paper Weight Range | 200 – 1000 g/m² |

| Production Capacity | Up to 36000 pcs/hour |

| Paper Size Range | Min: 150(L) × 160(W) mmMax: 780(L) × 880(W) mm |

| Window Size Range | Min: 30(L) × 50(W) mmMax: 350(L) × 400(W) mm |

| Film Thickness | 0.04 – 0.25 mm |

| Machine Power | 12 kW |

| Machine Weight | 2800 kg (2.8 tons) |

| Machine Dimensions (L × W × H) | 6700 × 1700 × 1600 mm |

Need a Custom Solution?

Get Your One-on-One Consultation

Struggling to find the perfect machine that fits your unique factory layout or production goal?

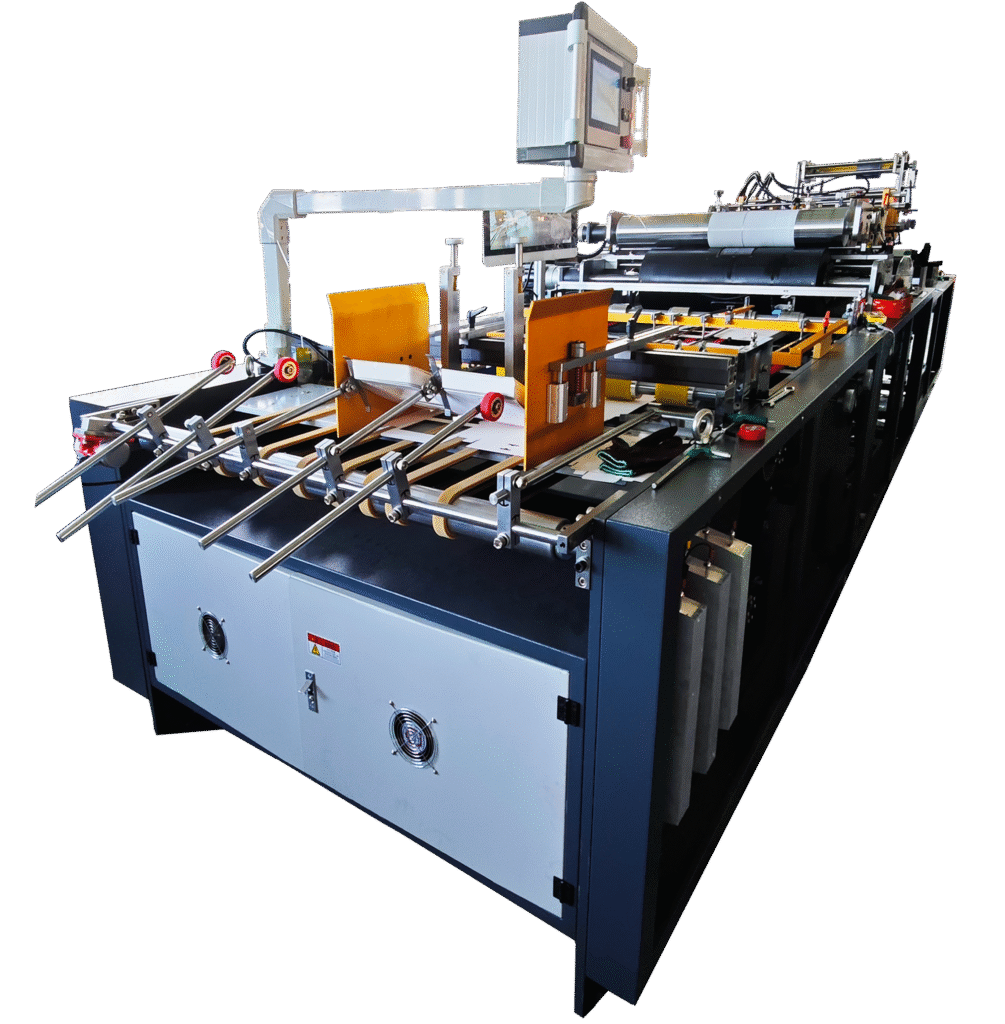

Window Patching Machine

In today’s competitive market, product presentation is everything. Our advanced window patching machine is the perfect solution for creating professional, eye-catching packaging with clear windows that showcase your products. This specialized piece of packaging machinery is essential for businesses looking to enhance their brand image and boost sales.

What is a Window Patching Machine?

A window patching machine is a specialized type of packaging machinery used to automatically apply a transparent film (a “patch”) to a pre-cut window on a paper or cardboard box. This process is common for products like electronics, toys, cosmetics, and food, where consumers need to see the item before purchasing. By creating a clear, secure window, the machine adds value, protects the product, and improves consumer confidence.

Key Features and Benefits

Our window patching machine is engineered for efficiency, precision, and versatility. It offers a range of features that set it apart:

- High-Speed Operation: Designed for rapid, continuous production, the machine can handle high volumes, helping you meet tight deadlines and scale your business.

- Precision Film Application: An advanced control system ensures the film is applied with perfect alignment, eliminating wrinkles and bubbles for a professional finish.

- Versatile Compatibility: The machine can handle various sizes and shapes of boxes and different types of film, including PVC, PET, and OPP, giving you the flexibility to produce a wide range of packaging.

- Reduced Waste: Precise control over film cutting and application minimizes material waste, saving you money and contributing to more sustainable operations.

- User-Friendly Interface: The intuitive control panel makes it easy for operators to set up and monitor production, reducing training time and improving overall efficiency.

Why Choose Our Packaging Machinery?

Choosing the right packaging machinery is a critical business decision. Our equipment is not just built for performance; it’s also designed for long-term reliability. We stand by our products, offering excellent customer support and service to ensure your production line runs smoothly. By investing in our window patching machine, you are upgrading your production capabilities and enhancing your brand’s appeal.

Ready to improve your packaging? Contact us today to learn how our packaging machinery solutions can help you create stunning, high-quality products that stand out on the shelf.