What is a disposable product? It’s any item designed for single use or short-term use before being thrown away. Think of the coffee cup you toss after your morning latte, the plastic fork from lunch takeout, or the paper towel you use for spills. These products prioritize convenience and hygiene over longevity.

Disposable products are everywhere in modern life. From plastic bags at checkout to surgical gloves protecting your dentist’s hands, we interact with dozens of single-use items daily. The global market represents a massive manufacturing sector engineered for high-volume, low-cost production.

Understanding disposable products matters because they shape how we live, work, and impact our environment. While these items deliver convenience and safety benefits, their widespread use creates challenges we’re all dealing with today.

TL;DR

- Disposable products are single-use items designed to be thrown away after one use

- Common examples include packaging materials, food service items, hygiene products, and medical supplies

- Manufacturing focuses on cost-effective production using materials like plastic, paper, and aluminum

- Environmental concerns include low recycling rates and accumulating waste

- Sustainable alternatives and circular economy approaches are reshaping the industry

Understanding Single-Use vs Reusable Products

The fundamental difference between disposable and reusable products comes down to intended lifespan and design philosophy. Single-use products get engineered for immediate disposal after fulfilling their purpose, while reusable items are built for repeated use over extended periods.

Businesses often choose disposable options for practical reasons beyond simple cost calculations. In food service, using disposable plates eliminates the need for dishwashing equipment, labor, and storage space. Healthcare facilities rely heavily on single-use medical devices to prevent cross-contamination between patients.

The convenience factor drives much of this preference. Disposable products reduce operational complexity by eliminating the logistics of collection, cleaning, and redistribution. For manufacturers, this creates predictable demand patterns and recurring sales opportunities that reusable products cannot match.

Types and Examples of Disposable Products

Disposable products span virtually every industry and application, from simple household items to sophisticated industrial components. Each category serves specific needs and requires different manufacturing approaches.

Modern single-use items reflect decades of innovation in materials science and manufacturing efficiency. What started with basic paper products has evolved into complex multi-layer materials with specialized coatings, barriers, and structures.

Understanding the full scope of disposable products helps businesses make informed procurement decisions. Different applications require different material properties, manufacturing tolerances, and performance standards. Healthcare disposables must meet sterility requirements, food service items need food-safe materials, and industrial applications often demand chemical resistance.

Kitchen and Food Service Disposables

Food service represents one of the largest disposable product sectors. Walk into any busy coffee shop during morning rush and you’ll understand why businesses rely on paper cups, plastic lids, disposable stirrers, and takeout containers.

The economics make sense when you break it down. A restaurant using disposable plates doesn’t need dishwashers, industrial dishwashing equipment, or space to store clean dishes. Restaurant and catering businesses depend heavily on single-use plastics examples like drink cups, food containers, and utensils. The global disposable cups market alone was valued at $17.40 billion in 2024.

Household and Consumer Disposables

Common disposable household items form a significant portion of daily consumer goods that most of us take for granted. This list of single-use items includes garbage bags, paper towels, disposable cleaning wipes, aluminum foil, and plastic wrap. Each product addresses specific convenience needs while generating consistent replacement demand.

Shopping bags represent another major category, with the ongoing debate around disposable vs reusable bags highlighting the complexity of environmental and practical considerations.

Medical and Hygiene Products

Healthcare generates enormous volumes of disposable products designed for infection control and patient safety. Medical disposables include syringes, gloves, masks, surgical gowns, and specialized equipment coverings. These products often require specific materials and manufacturing processes to meet stringent safety standards.

Personal hygiene represents another substantial segment, encompassing items like diapers, feminine hygiene products, and disposable razors. The global disposable hygiene products market reached $194.25 billion in 2024 and is projected to grow to $348.03 billion by 2032.

Industrial and Packaging Applications

Industrial operations use disposable products for packaging, protection, and process efficiency. These include shipping containers, protective wrapping, and specialized industrial films. Manufacturing companies often choose disposable packaging solutions to reduce handling costs and improve shipping efficiency.

The disposable packaging market spans everything from food containers to electronics protection, with flexibility and cost-effectiveness driving adoption across industries.

| Product Category | Primary Materials | Typical Lifespan | Main Applications |

| Food Service | Paper, plastic, aluminum | Minutes to hours | Restaurants, catering, takeout |

| Household | Plastic, paper, non-woven | Single use | Cleaning, storage, convenience |

| Medical | Specialized plastics, non-woven | Single patient use | Healthcare, safety |

| Industrial | Various plastics, cardboard | Single shipment | Packaging, protection |

Environmental Impact of Disposable Products

The environmental consequences of disposable products create some of the most pressing challenges we face today. The scale of impact extends from production through disposal, touching every part of our daily lives.

Here’s a statistic that might surprise you: only 9% of plastic waste globally gets recycled successfully, according to OECD data. The vast majority ends up in landfills, gets incinerated, or contaminates our environment.

Manufacturing these products creates significant environmental costs before they even reach consumers. The carbon footprint of disposable products extends beyond just the items themselves.

Consider this: humanity was expected to consume over 500 million tonnes of plastics in 2024 alone, according to UN Environment Programme data. That’s roughly equivalent to the weight of 2,500 Empire State Buildings worth of plastic, used and discarded in a single year.

Plastic production alone generated 1.8 billion tons of greenhouse gas emissions in 2019, representing 3.4% of global emissions. Marine pollution represents another critical concern. Approximately 8 million tons of plastic waste enter oceans annually, with single-use items comprising a significant portion. Europeans alone generate an average of 36.1 kilos of plastic packaging waste per person annually, according to European Parliament data.

Why are disposable products bad for the environment becomes clear when examining their lifecycle. Most disposable items persist in the environment for hundreds of years while serving their intended purpose for minutes or hours. A plastic bag that carries your groceries for 20 minutes might sit in a landfill for 500 years.

Manufacturing and Business Considerations

Manufacturing disposable products requires specialized equipment and processes optimized for high-volume, low-cost production. Companies like Plentiful Choices provide industrial machinery solutions that enable efficient manufacturing across various sectors.

Modern disposable product machinery can produce thousands of items per hour, but achieving that speed while maintaining quality requires sophisticated engineering. When you’re making products that sell for pennies, every fraction of a second in production time matters.

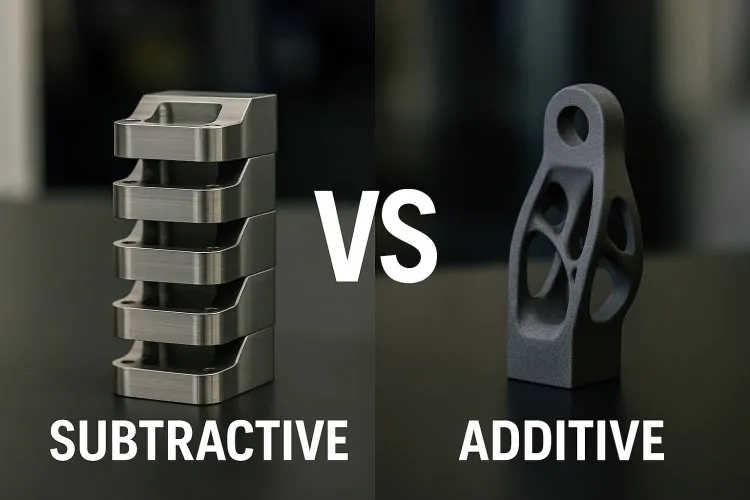

Different production approaches suit different needs. The pulp and paper industry uses continuous forming processes for paper cups and plates, while aluminum stamping creates disposable food containers, and non-woven fabric production makes everything from wet wipes to surgical gowns.

Manufacturing costs must stay extremely low to maintain competitive pricing. This drives continuous innovation in production efficiency, material utilization, and automated processing systems. A well-planned production line strategy becomes particularly important given the high-volume, low-value nature of most disposable products.

Why are disposable products so popular from a business perspective? They generate recurring revenue streams while eliminating customer maintenance responsibilities. This model appeals to both manufacturers seeking predictable sales and businesses wanting simplified operations.

Sustainable Alternatives and Solutions

The growing environmental awareness has sparked innovation in sustainable disposable products and alternatives that address traditional environmental concerns while maintaining practical benefits.

Biodegradable materials represent one promising direction, though it’s more complicated than you might think. Materials like PLA (polylactic acid), bagasse (sugarcane pulp), and bamboo offer similar functionality to traditional plastics while decomposing more readily in appropriate conditions. The catch? They often require specific composting infrastructure that may not be widely available.

The development of circular economy approaches offers another path forward. Rather than the traditional linear “take-make-dispose” model, circular approaches emphasize material recovery, reuse, and regeneration. This requires collaboration between manufacturers, waste management systems, and policy frameworks.

Innovation in material science continues to advance rapidly. Companies are developing new bio-based materials, improving recycling technologies, and creating products designed for end-of-life recovery. Government regulations increasingly influence disposable product development, with plastic bag bans and single-use plastic restrictions creating both challenges and opportunities.

What is the difference between single-use and reusable products is becoming less clear as innovations blur traditional boundaries. Some modern “disposable” products incorporate reusable components or enable multiple use cycles before disposal.

Conclusion

Understanding what is a disposable product becomes increasingly important as we navigate environmental challenges and business decisions. These single-use items represent a fundamental aspect of modern manufacturing and consumption, providing convenience and safety benefits while creating environmental challenges that require thoughtful solutions.

The future of disposable products lies in balancing practical needs with environmental responsibility. This requires continued innovation in materials, manufacturing processes, and waste management systems. Companies that successfully navigate these challenges while maintaining operational efficiency will be best positioned for long-term success.

For businesses evaluating disposable vs reusable options, the decision involves weighing immediate costs against long-term environmental and regulatory considerations. What matters most is understanding your specific needs and constraints rather than following one-size-fits-all advice.

FAQ

Yes, disposable products create significant environmental challenges due to low recycling rates, resource consumption, and waste accumulation. However, they also provide important safety and convenience benefits that must be balanced against environmental costs.

A single-use product is any item designed to be used once and then thrown away. Examples include plastic water bottles, paper napkins, and disposable masks

Businesses choose disposable products to reduce cleaning costs, eliminate maintenance requirements, ensure hygiene standards, and simplify logistics. The convenience often outweighs the higher per-use costs.

Common disposable products include plastic bags, paper plates, disposable cups, food packaging, medical gloves, cleaning wipes, and takeout containers. These span household, commercial, and industrial applications.

Manufacturers can improve sustainability by using biodegradable materials, designing for recyclability, reducing packaging waste, and implementing circular economy principles in their production processes