1. Investment Budget

A fundamental starting point is evaluating the total budget, which includes both the initial investment—covering machinery and infrastructure—and ongoing operational costs such as raw materials, labor, and energy consumption.

Aligning machine selection with financial constraints ensures better ROI and long-term sustainability.

2. Product Thickness Range & Market Applications

The target thickness range of your final products is a critical determinant in machinery configuration:

– 50–100 microns: Ideal for labels, flexible packaging, and sustainable films.

– 100–300 microns: Suited for maps, brochures, and printable materials.

– 300–700 microns: Best for rigid applications like trays, tags, and thermoformed goods.

Matching machinery to product thickness ensures market suitability and performance reliability.

3. Product Performance Specifications

Each machine should support your product’s required specifications, including:

– Width

– Density

– Tear strength

– Elongation

– Stiffness

These characteristics must align with industry standards and customer expectations for different product applications.

4. Workforce Requirements

Labor considerations vary by automation level:

– Fully automated systems typically require only 2–3 operators.

– Semi-automated lines may need more skilled personnel for optimal operation.

Factoring in labor availability and skill level helps manage operational complexity and costs.

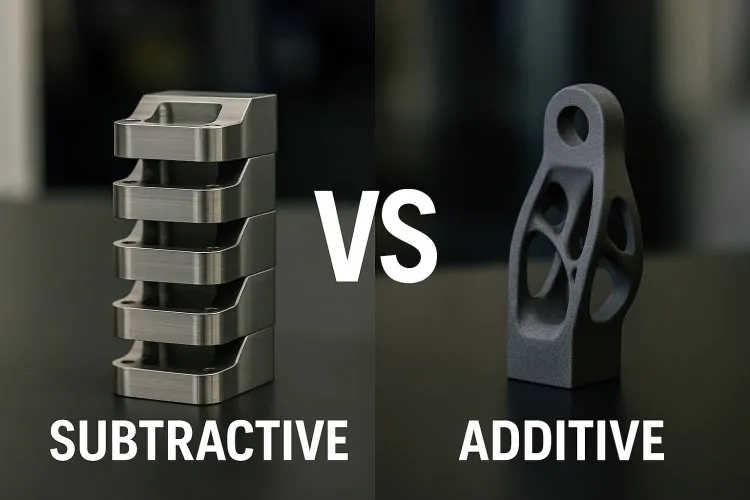

5. Machine Technology and Configuration

Technology selection should be guided by:

– Product specifications

– Budget limitations

– Desired thickness range

– Availability of raw materials

The right technology enables efficient production and consistent quality output.

6. Location and Environmental Conditions

The production environment directly affects machine performance:

– Humidity control helps prevent material defects.

– Stable power supply and logistics accessibility enhance operational consistency.

– Regulatory compliance is crucial for sustainable operations.

Ensuring a controlled environment reduces risks and improves output quality.

7. Equipment and Supplier Quality

Investing in high-performance components—such as VFDs, melt pumps, T-dies, scanners, and extrusion systems—is essential.

Collaborating with reputable global suppliers ensures dependable service and long-term machine reliability.

8. Quality Enhancement Systems

Supporting equipment plays a key role in refining product quality:

– Corona treatment units improve print and coating adhesion.

– Anti-static devices facilitate safer and smoother material handling.

– Automated defect detection ensures consistent quality control.

9. Critical Machine Components & Post-Processing Equipment

Your production line should include:

– Melt pumps, trimmers, and cooling systems for core processes.

– Coating, printing, embossing, and cutting units for value-added finishing.

Integrating these systems enhances product versatility and competitiveness.

10. Facility Infrastructure

Efficient production also depends on the physical setup:

– Sufficient space for machinery

– Adequate ventilation and climate control

– Safety standards and effective waste management

Proper factory layout streamlines workflow and supports regulatory compliance.

Final Thoughts

Choosing the right machinery is more than just a technical decision—it’s a holistic approach that considers financial viability, operational efficiency, and market requirements. By carefully evaluating these factors, manufacturers can establish a production line that delivers both high performance and sustainable profitability.

Need expert guidance? Contact us today for a tailored solution!