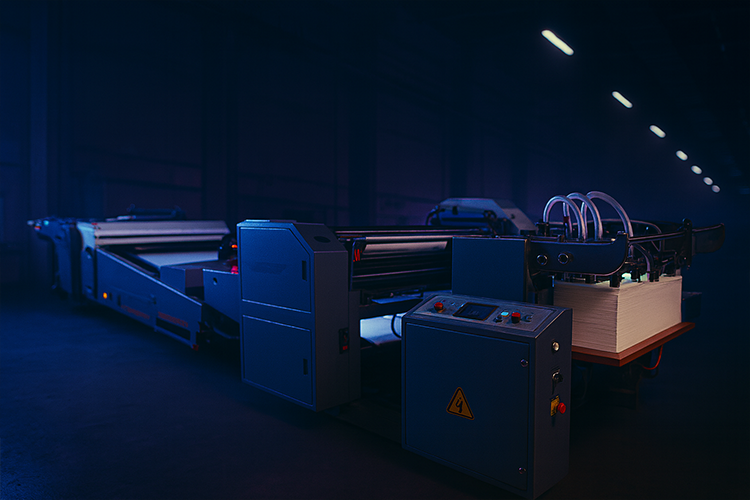

How Does a Coating Machine Work?

A coating machine applies a functional layer to a substrate to enhance its properties. The specific mechanism depends on the type of machine and the application. Different types of coating machines are designed for various materials, from paper and film to self-adhesive labels and protective films.

Coating machines typically operate on a roll-to-roll system, processing large rolls of material and applying a liquid or adhesive layer before it is rewound into a finished roll. The general process involves several key steps:

- Unwinding: A roll of the base material, or substrate, is fed into the machine from an unwinding unit. This unit often includes a tension control system to ensure a smooth, stable feed.

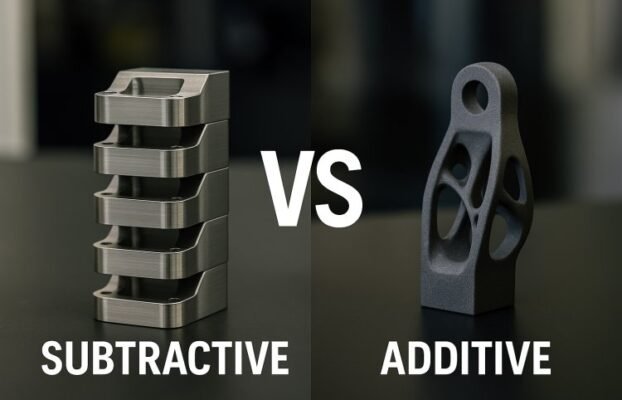

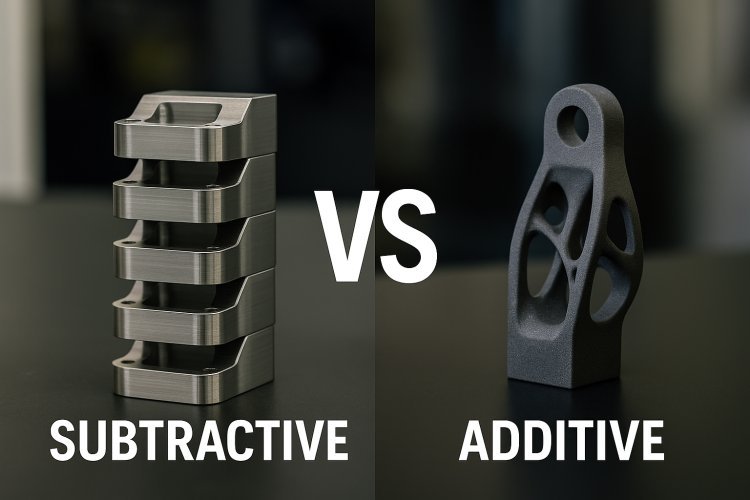

- Coating Application: The core of the process involves applying the coating material. Different machines use different methods depending on the desired outcome:

- Mayer Bar Coating: This method uses a wire-wrapped rod to apply a precise and uniform layer of adhesive, often used for materials like polyethylene (PE) protective films.

- Comma Blade Coating: This technique uses a blade to spread a coating, such as various adhesives, with high precision. It is used in machines that produce self-adhesive labels and stickers.

- Air Knife Coating: This method uses a blade of high-pressure air to remove excess coating and ensure a smooth, even application, which is suitable for producing waterproof paper.

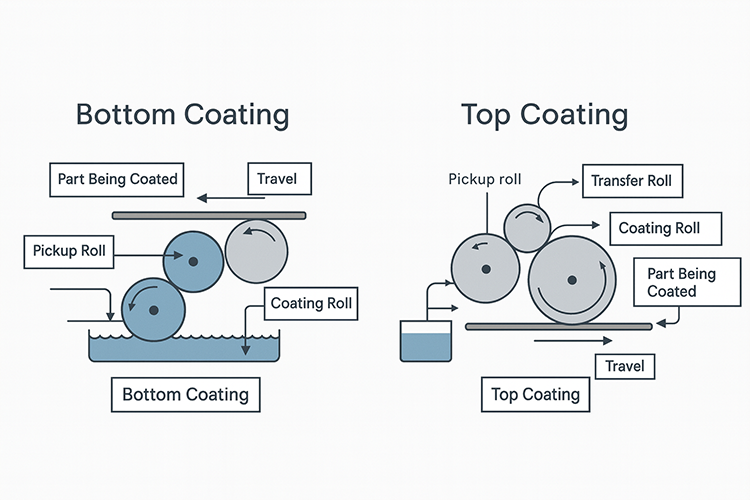

- Roller Coating: This is a common method for applying melted wax to papers to make them moisture-resistant and greaseproof. A 5-roller system is used for applying silicone to release liners for labels and tapes.

3. Drying/Curing: After the coating is applied, the material passes through a drying or curing system to set the layer. These systems can use heat from electric heaters, gas, hot oil, or even UV light.

4. Rewinding: The coated and dried material is then wound into a finished roll at the rewinding unit.

What is the purpose of coating machines?

Coating machines apply a layer of material to a substrate’s surface to enhance its properties. The primary purpose of these machines is to add specific functionalities like protection, decoration, or performance enhancement to a wide range of products across various industries. Key Purposes of Coating:

- Protection: Coatings serve as a barrier against environmental factors. For example, they can provide corrosion protection on metal parts in the automotive industry, shield sensitive electronics from moisture, or protect pharmaceuticals from light and oxygen, thereby extending their shelf life.

- Aesthetics and Decoration: Coating machines are used to improve a product’s visual appeal. This includes applying paint for color and gloss on consumer goods and furniture, or creating a smooth finish on tablets to make them easier to swallow and more appealing to patients.

- Performance Enhancement: Coatings can give a product new or improved functional properties. Examples include anti-reflective coatings on lenses for better vision, non-stick coatings on cookware, and conductive coatings on circuit boards. In pharmaceuticals, coatings can control the release of a drug, creating sustained-release or enteric-coated tablets that dissolve at a specific time or location in the body.

- Durability and Wear Resistance: By adding a hard, durable layer, coating machines increase the lifespan of a product. This is crucial for industrial tools and automotive parts that are exposed to wear and tear.

Types of Coating Machines

Coating machines are an essential part of modern industrial production. Coating machines are widely used for applying a thin layer of material onto paper, film, foil, textiles, and other substrates. These machines enhance product functionality by adding properties such as protection, aesthetics, barrier performance, or printability.

In fact, coating machines are considered a key category within converting machines, as they transform raw or semi-finished materials into value-added products through specialized surface treatments. Different types of coating technologies are available—such as gravure, slot-die, reverse roll, and curtain coating—each suited for specific applications depending on coating thickness, material compatibility, and production requirements.

Coating and Laminating Machine

A coating and Laminating Machine is used to produce self-adhesive labels and stickers. It applies adhesives to various materials, including standard paper, plastic films (PP, PET), and stone paper. It uses a comma blade coating method, which is a type of reverse-roll coating, to precisely apply the adhesive. The machine operates at high speeds in a roll-to-roll production format and includes real-time process control to ensure consistent quality.

Coating Machine for Waterproof Paper Production

This equipment applies protective layers to paper to make it resistant to water and moisture. It can use materials like polyethylene, latex, or wax. The machine uses an Air Knife Coating Unit, which uses a high-velocity jet of air to remove excess coating, leaving a smooth and uniform layer. It is commonly used to produce materials for food packaging, outdoor maps, and industrial labels.

Coating Machine for PE Self-Adhesive Protective Films

This specialized machine applies adhesive layers to polyethylene (PE) films. It uses a Mayer Bar coating unit, a simple and effective method that applies a controlled thickness of adhesive using a wire-wound rod. This machine is ideal for creating protective films for surfaces like home appliances, glass, and aluminum sheets, providing a temporary shield against scratches and damage.

Silicone Coating Machine

Silicone Coating Machine is designed to apply a uniform layer of silicone onto substrates like glassine paper, PET film, or PE-coated kraft. The resulting product is a release liner that acts as the backing for self-adhesive labels, medical patches, and industrial tapes. This machine can be equipped with various coating units, including a 5-Roller, slot-die, or gravure coating unit, depending on the desired thickness and precision.

Wax Coating Machine

This machine applies melted paraffin wax or other waxes to paper to make it greaseproof and moisture-resistant. It is widely used in the food packaging industry for items like burgers and cheese, as well as for wrapping cosmetics and protecting industrial metal parts. The wax coating provides an effective barrier, preventing liquids and grease from seeping through the paper.

Advantages of Coating Machines

To better understand the role of these converting machines, it is important to explore their key strengths. The following table outlines the main advantages of coating machines, showing how they add value to materials and improve overall production efficiency.

| Advantage | Description |

| Enhanced Protection | Provides resistance against moisture, chemicals, and physical damage. |

| Improved Appearance | Adds gloss, smoothness, or desired surface finish for better aesthetics. |

| Functional Properties | Enables special features such as barrier layers, heat resistance, or printability. |

| Increased Durability | Extends the lifespan of materials and final products. |

| Cost Efficiency | Reduces waste and optimizes material usage during production. |

| Versatility | Can be applied on various substrates like paper, film, foil, and textiles. |

Coating Machines: Adding Value to Materials

When discussing modern industrial production, one important question often arises: What is a coating machine? A coating machine is not just a simple tool but a vital part of converting technology that adds value to raw materials through precise surface treatments. By enhancing protection, improving product appearance, and introducing functional properties, coating machines play a crucial role in a wide range of industries. Their ability to deliver consistent quality while increasing efficiency makes them indispensable for companies aiming to remain competitive in today’s market.

PlentifulChoices provides a wide range of solutions and offers for businesses looking to set up coating lines or invest in coating machines. Whether a company needs guidance on selecting the right technology, turnkey installation support, or cost-effective purchase options, PlentifulChoices ensures flexible packages tailored to different production requirements. With these comprehensive services, customers can confidently choose the best coating machines and maximize the efficiency of their manufacturing processes.