Most people think choosing between additive and subtractive manufacturing is purely about comparing machine costs until they realize tooling expenses alone can kill their budget. Additive manufacturing cost typically runs lower for small batches of 1 to 50 units, while subtractive methods become economical beyond 100 to 250 units. The break-even point shifts based on part complexity, material selection, and geometric requirements. Additive processes eliminate tooling costs entirely but charge premium prices for materials, whereas CNC machining demands significant upfront tooling investment that spreads across larger production volumes.

TL;DR

- Additive manufacturing cost runs lower for batches under 50 units—the economics favor AM at small volumes

- CNC machining takes over at higher volumes thanks to faster production speeds that actually matter

- Material waste tells the real story: 30-70% for machining versus 5-10% for 3D printing

- Break-even happens somewhere between 50 to 250 parts, shifting based on how complex your design gets

- Industrial AM systems demand $100,000 to $500,000 upfront—that depreciation hits hard at low volumes

- Complex geometries destroy CNC budgets but barely touch AM costs—this changes everything for intricate parts

Understanding Additive and Subtractive Manufacturing

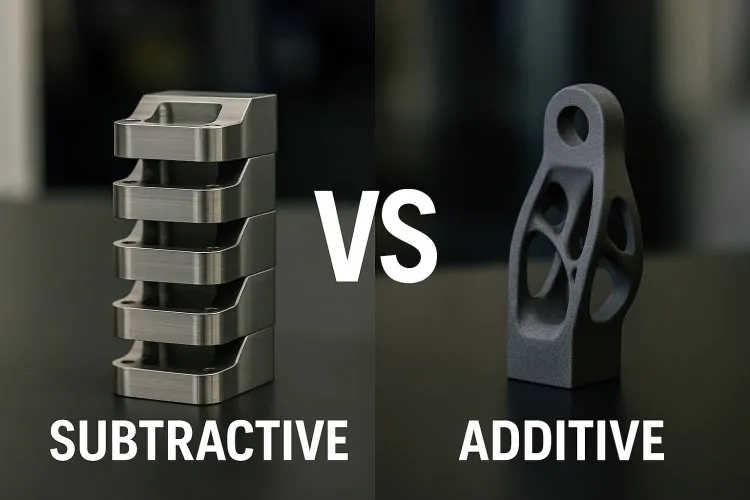

Additive manufacturing builds objects layer by layer from digital models, depositing material only where needed. This process includes technologies like FDM, SLS, and DMLS that create parts without removing material from a stock block. Subtractive manufacturing removes material from a solid workpiece using cutting tools, milling machines, or waterjet systems to achieve the desired shape. The fundamental difference lies in the material approach. Additive processes add material incrementally, while subtractive methods carve away excess material. This distinction creates vastly different cost structures. Understanding these core differences is essential before evaluating which method offers better economics for your specific production needs. Manufacturing cost comparison requires examining how each process handles materials, labor, tooling, and time-to-market factors.

Additive Manufacturing Cost vs. Subtractive Manufacturing Cost: Complete Breakdown

Manufacturing decisions require a comprehensive cost analysis across multiple factors. Both additive and subtractive methods present distinct economic profiles that shift based on production volume, part complexity, and material requirements.

Initial Capital Investment

High capital investment hits you hard with both manufacturing methods. Industrial additive manufacturing systems cost $340,000 to $1,040,000 for metal-based equipment, while polymer systems range from $100,000 to $400,000. CNC machining centers cost $50,000 to $500,000 depending on axis configuration. Equipment costs eat up 45% to 74% of your total additive manufacturing expenses based on NIST research. Additive manufacturing cost structure remains heavily weighted toward equipment depreciation rather than operational expenses—a critical distinction when calculating true per-part economics.

Material Costs and Efficiency

Material efficiency creates one of the biggest cost differences you’ll see between these manufacturing approaches. Here’s what actually happens: CNC milling throws away 30% to 70% of your raw material depending on part geometry. When you start with a $500 titanium billet for an aerospace component and watch $350 turn into scrap, you feel that waste in every budget meeting. Material wastage at this scale means your scrap rate directly impacts profitability—especially with expensive alloys.

Additive manufacturing waste runs between 5% and 15%—dramatically better material utilization. The catch? AM materials cost substantially more per kilogram. Metal powders for SLS (Selective Laser Sintering) and DMLS (Direct Metal Laser Sintering) run $54 to $600 per kilogram compared to $2 to $50 per kilogram for traditional metal stock. Even FDM (Fused Deposition Modeling) polymer materials cost more than bulk plastic. This creates an interesting economic dynamic where you use less material but pay more for every gram consumed.

The relationship between manufacturing efficiency and production line strategy becomes crystal clear when evaluating total material expenses. Companies constantly balance raw material costs against waste reduction, trying to determine which approach actually saves money rather than just looking good on paper.

Labor and Automation Costs

Labor automation handles the repetitive work while humans focus on oversight and post-processing, which explains why direct labor rarely exceeds 10% of total costs for either method. The real difference shows up in setup time. CNC operations demand hours of programming and fixturing, while AM systems just need a loaded file anda prepped build platform.

Tooling and Setup Costs

Tooling elimination represents additive manufacturing’s most compelling advantage. Traditional CNC requires cutting tools, jigs, and fixtures costing $5,000 to $100,000, depending on complexity. When you’re manufacturing 20 custom brackets, that $8,000 tooling cost adds $400 to every single part before machining even starts. CNC setup fees run $50 to $1,000 per job, plus $50 to $200 per cutting tool replacement.

Additive manufacturing eliminates all of this. The same printer produces vastly different geometries without retooling. Industries focused on stone paper production cost optimization recognize similar benefits when adopting flexible manufacturing technologies.

Post-Processing and Finishing Costs

CNC-machined parts often require minimal finishing, achieving desired surface quality directly from machining—typically 1.6 to 3.2 Ra without extra processing. Additive-manufactured components need substantial post-processing: support removal, heat treatment, and surface finishing that adds $100 to $500 per part. Manual finishing costs $20 to $50 per hour, while automated processes add $10 to $100 per part. When running your 3D printing cost analysis, post-processing expenses often surprise newcomers who focused exclusively on machine and material costs.

Build Time and Production Speed

CNC machining produces parts faster once the setup is complete—a metal bracket takes 30 to 90 minutes versus 5 to 15 hours for selective laser sintering. When you run the numbers on the NC machining cost analysis above 250 units, production speed becomes the decisive factor.

However, AM’s ability to produce multiple parts simultaneously in a single build partially offsets this speed disadvantage. A powder bed fusion system might fabricate 50 identical components in the same time required for a single part. Build time determines how many parts you can produce per machine per day, which affects your cost per part more than most people realize.

| Cost Factor | Additive Manufacturing | Subtractive Manufacturing |

| Machine Investment | $100K-$1M | $50K-$500K |

| Material Efficiency | 85-95% utilized | 30-70% utilized |

| Material Cost | $54-$600/kg | $2-$50/kg |

| Tooling Cost | $0 | $5K-$100K |

| Setup Time | 30-60 minutes | 2-8 hours |

| Labor Cost | 5-10% of total | 5-10% of total |

| Post-Processing | High requirement | Low requirement |

Break-Even Volume Analysis

Understanding break-even points between manufacturing methods enables informed production decisions. Volume thresholds shift based on part geometry, material selection, and required tolerances.

Low-Volume Production (1-50 Units)

Additive manufacturing dominates this segment completely. Tooling costs for CNC would kill your budget before you made your first part. Cost per part stays relatively flat regardless of quantity—anywhere from $50 to $500 per component for typical industrial applications. A 2024 study comparing manufacturing methods found AM costs roughly $140 less per part than CNC machining for aerospace components when you’re making fewer than 50 units.

The economic advantage intensifies for complex geometries. When you’re doing rapid prototyping or building custom parts that need multiple CNC setups, AM saves you from hemorrhaging cash on specialized tooling. Time-to-market matters more than cost per part in this range—getting your product out three weeks faster can mean the difference between capturing a market and missing it entirely. Here’s where design freedom actually matters financially: you can optimize part consolidation, reduce assembly costs, and improve performance without economic penalty.

Medium-Volume Production (50-250 Units)

The medium-volume range represents the competitive battleground between these technologies. Break-even typically occurs between 50 and 250 parts, depending heavily on geometric complexity. Simple brackets might favor CNC machining at 100 units, while complex housings with internal features remain cost-effective via AM up to 200 units. Here’s where AM vs SM unit cost stops following predictable patterns—the economics flip dramatically based on your specific part characteristics rather than following universal rules.

Part complexity drives the decision more than anything else in this range. Research indicates that parts with geometric complexity benefit from AM even at higher volumes, while simple geometries shift to subtractive methods sooner. How tight your tolerances need to be also matters here—CNC machining delivers more consistent dimensional accuracy than most AM processes.

High-Volume Production (250+ Units)

Subtractive manufacturing clearly wins at high volumes where tooling costs amortize across hundreds or thousands of parts. Subtractive manufacturing cost per unit drops significantly once you pass the 250-unit threshold, often falling below $50 per part for production runs exceeding 500 units. Superior production speed allows CNC operations to complete parts in minutes rather than hours.

Mass production scenarios above 1,000 units almost always favor traditional manufacturing unless parts require impossible geometries or frequent design iterations. The economics shift completely at these volumes—what seemed expensive in tooling becomes irrelevant when divided across thousands of parts.

Technology-Specific Cost Considerations

Different additive and subtractive technologies present varying cost profiles. Selecting the appropriate process for your application requires understanding these economic nuances.

FDM, SLS, and DMLS for Additive Manufacturing

Fused Deposition Modeling represents the most economical AM approach for polymer parts, with entry-level industrial systems starting around $50,000 and material costs of $20 to $80 per kilogram. FDM suits functional prototypes and low-stress components, offering rapid turnaround at moderate costs.

Selective Laser Sintering handles both polymers and metals with higher accuracy than FDM. Industrial SLS systems cost $200,000 to $500,000, while Direct Metal Laser Sintering equipment reaches $500,000 to $1,000,000. Material expenses for metal powders range from $50 to $600 per kilogram, depending on alloy composition.

Powder Bed Fusion technologies deliver superior mechanical properties and surface finish compared to FDM, justifying higher costs for demanding applications. These systems excel at producing end-use parts requiring excellent dimensional accuracy and material properties.

CNC Milling and Waterjet Cutting for Subtractive Manufacturing

Three-axis CNC milling provides cost-effective machining for straightforward geometries, with hourly rates between $20 and $40. Complex parts requiring four-axis or five-axis machining incur higher costs of $40 to $150 per hour due to equipment expense and programming complexity.

Waterjet cutting offers economical material removal for flat or moderately contoured parts, particularly with difficult-to-machine materials. Operating costs range from $50 to $100 per hour, making waterjet an attractive option for cutting operations on thick materials or exotic alloys.

Hybrid Manufacturing Approaches

Combining additive and subtractive processes creates hybrid solutions that leverage the strengths of both technologies. Hybrid systems can reduce costs by using AM for complex internal features while employing CNC machining for critical surface finishes and tight tolerances. These integrated approaches represent the future of cost-effective manufacturing for complex, high-value components.

| Production Volume | Cost-Effective Method | Typical Cost Per Part | Key Consideration |

| 1-50 units | Additive | $100-$500 | No tooling costs, design freedom |

| 50-250 units | Either method | $80-$250 | Break-even zone, complexity-dependent |

| 250+ units | Subtractive | $30-$100 | Production speed wins |

Conclusion

Manufacturing cost comparison reveals distinct economic territories. Additive manufacturing cost advantages dominate low-volume production and complex geometries. Subtractive manufacturing wins at higher volumes where tooling costs amortize and production speed matters. Break-even typically falls between 50 and 250 parts based on complexity. The additive manufacturing sector continues to accelerate—global 3D printer shipments reached 2.2 million units in 2021, with projections to 21.5 million by 2030 [1], while desktop printers now capture 55.9% of the market[2]. Forward-thinking manufacturers increasingly adopt hybrid manufacturing that combines additive and subtractive processes in single workflows. Companies like Plentiful Choices position their production line capabilities to accommodate both traditional and advanced manufacturing technologies, recognizing that the question has shifted from “additive or subtractive” to “which combination delivers optimal results?”

References

- [1] Grand View Research. “Additive Manufacturing Market Size, Share & Trends Analysis Report.” https://www.grandviewresearch.com/industry-analysis/additive-manufacturing-market

- [2] Coherent Market Insights. “Additive Manufacturing Market Report.” https://www.coherentmarketinsights.com/industry-reports/additive-manufacturing-market

FAQ

Additive manufacturing cost advantages center on eliminated tooling expenses but come with higher material costs and slower production speeds. Subtractive manufacturing requires significant tooling investment but achieves lower per-unit costs at higher volumes. The cost advantage shifts based on production quantity and part complexity.

Break-even typically occurs between 50 and 250 units, depending on part complexity and material. Simple geometries favor CNC machining at lower volumes around 75-100 units, while complex parts remain cost-effective via AM up to 200-250 units.

Complex geometries increase CNC machining costs substantially due to additional setups, specialized tooling, and extended machining time. Additive manufacturing costs remain relatively stable regardless of complexity, making AM economically attractive for intricate designs.