Most manufacturing professionals use these terms interchangeably until they actually need to set up a facility. Here’s the thing: choosing between a production line vs. an assembly line affects everything about how your facility operates. Production lines transform raw materials through multiple processes into finished products. Assembly lines take premade components and put them together in sequence. Whether you need a manufacturing line vs. an assembly line depends on what you’re making, and getting this right matters for equipment purchases, factory layouts, and hiring decisions.

Why Manufacturing Terminology Actually Matters

The confusion between production and assembly lines costs businesses real money. I’ve seen companies order the wrong equipment because they used the terms interchangeably. When you tell a supplier you need a production line but describe an assembly process, you’ll get quotes that don’t match what you actually need.

The distinction affects your entire operation. Production lines require different space layouts, material handling systems, and worker skill sets compared to assembly lines. A stone paper manufacturing facility needs production line capabilities for transforming raw calcium carbonate and resin into paper sheets. An electronics company assembling laptops needs assembly line setups where workers install pre-made screens, keyboards, and batteries.

Getting this right from the start saves you from costly redesigns later. Most facilities need both types of processes working together, but understanding which is which helps you plan capacity, hire the right expertise, and communicate clearly with equipment vendors.

Production Line vs Assembly Line: The Core Differences

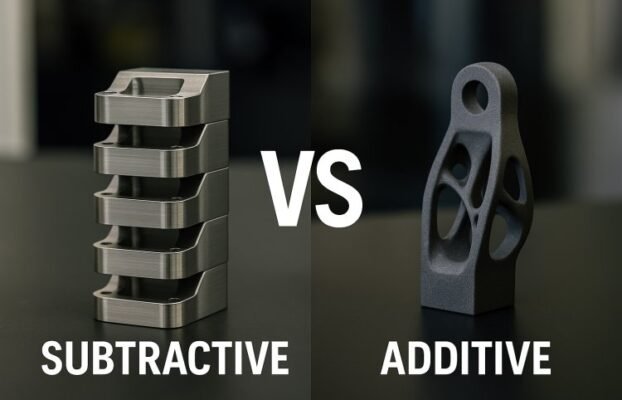

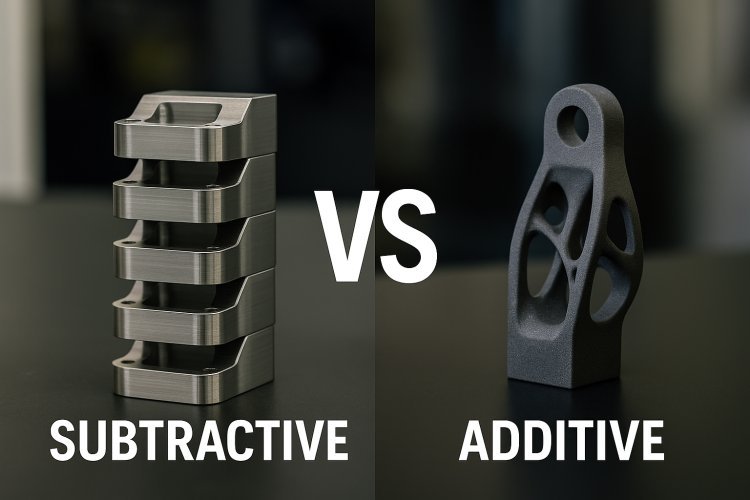

Your manufacturing process flow—how materials move through your facility – determines which system you’re using. Production lines handle continuous material transformation. Assembly lines focus on joining components. Here’s what actually separates them.

What a Production Line Actually Does

A production line transforms raw materials through multiple distinct processes. Here’s the simple production line definition: it’s the complete journey from basic materials to finished products. Industrial production lines handle a broad scope of operations—cutting, shaping, welding, coating, curing, and testing.

Component fabrication happens on production lines where raw materials get modified. A steel production line takes iron ore and transforms it through smelting, rolling, and finishing. Each stage changes the material’s form and properties. Workers and machines perform different types of operations at each station. Here’s the key difference: component fabrication vs joining. Fabrication changes raw materials, while joining just connects pre-made parts without any material transformation.

Production lines can include assembly stages, but they’re not limited to assembly. The system encompasses every process needed to create a product from scratch. Facilities that handle multiple process types need careful planning. A comprehensive production line strategy addresses equipment selection, workflow optimization, and material handling across all manufacturing stages.

What an Assembly Line Actually Does

What does an assembly line actually mean? It’s all about sequential component integration. Assembly lines focus on sub-assembly integration and final product assembly. Workers at fixed stations add specific components as products move past them on conveyors or carts. Each workstation completes one task before the product advances to the next position.

The Ford assembly line revolutionized manufacturing in 1913 by breaking car assembly into sequential tasks. Production time dropped from 12.5 hours to 93 minutes for a Model T [1]. Workers specialized in single tasks rather than building entire vehicles. This principle still drives modern assembly operations.

Assembly requires premade parts ready for installation. An appliance assembly line receives motors, housings, and control panels that were manufactured elsewhere. Workers connect these components following a specific sequence. The product gains functionality as it progresses through stations, but no fundamental material transformation occurs.

Scope of Industrial Production Line vs Assembly Line

Each approach requires different production system components. Production lines integrate multiple manufacturing processes, including machining, treatment, and finishing operations. Quality control happens throughout the entire process as materials change form.

Assembly plays a specific role in production—it’s just one stage within a larger system. Modern facilities often combine both approaches. A smartphone manufacturer runs production lines for creating circuit boards and cases, then feeds those components into assembly lines where workers put devices together.

Where does the assembly line fit in supply chain workflows? It serves as the final manufacturing stage. Products arrive with all components manufactured upstream and ready for integration. Production lines operate earlier, handling raw materials directly from suppliers before parts reach assembly stations.

| Aspect | Production Line | Assembly Line |

| Input Materials | Raw materials requiring transformation | Pre-manufactured components |

| Process Type | Multiple operations (cutting, forming, treating) | Sequential joining and installation |

| Output | Finished products or sub-components | Assembled final products |

| Worker Skills | Diverse technical capabilities | Specialized assembly tasks |

| Equipment | Machine tools, furnaces, coating systems | Conveyors, fastening tools, testing stations |

The Ford Assembly Line: How It Changed Everything

Henry Ford didn’t invent the assembly line, but he perfected it for automobile manufacturing. Before 1913, car production meant skilled teams building entire vehicles at stationary positions. Ford split the process into 84 distinct steps performed by workers at dedicated stations.

The moving chassis transformed manufacturing economics. Workers stayed in position while products moved to them on conveyor systems. This eliminated the time workers spent walking between parts and tools. The concept was borrowed from meatpacking plants, where overhead trolleys moved carcasses past butchers who removed specific cuts.

The impact spread beyond automotive manufacturing. Other industries adopted assembly line principles for everything from electronics to furniture. The pulp and paper industry implemented continuous production lines that combined material processing with assembly concepts for finishing operations.

Modern assembly lines bear little resemblance to Ford’s original setup. Robots handle repetitive tasks. Sensors track every movement. Workers focus on complex installations that require human judgment. But the core principle remains: breaking complex production into sequential, specialized tasks increases output dramatically.

Production and Assembly Lines in Modern Manufacturing

Assembly line automation has transformed what these systems can accomplish. Industrial automation demand is growing 9.3% annually and will reach $307.7 billion by 2030 [2]. Robots perform welding, painting, and fastening with precision that humans can’t match consistently.

Mass production systems today integrate digital controls throughout manufacturing operations. Sensors monitor every station in real time. When production slows at one point, the entire system adjusts automatically. This level of coordination was impossible when Ford started his assembly lines.

The distinction between production and assembly lines blurs in modern smart factories. A single facility might run continuous production processes for creating components, then shift those parts directly into assembly operations without human handling. Material moves automatically based on digital instructions.

Companies now use data analytics to optimize their manufacturing process flow. Tracking cycle times, defect rates, and equipment performance across production and assembly operations helps identify bottlenecks, whether they occur in raw material processing or final assembly stages.

By 2024, 60% of companies will have implemented automation [3] across their manufacturing operations. This adoption changes how businesses think about production vs. assembly decisions. Automation makes it easier to combine both concepts in flexible manufacturing cells.

How Plentiful Choices Optimize Both Systems

At Plentiful Choices, we’ve spent years helping businesses implement both production lines and assembly operations. Our industrial services division handles everything from initial facility planning through equipment installation and system integration.

Stone paper manufacturing showcases how production and assembly concepts work together. The process starts with production line operations where calcium carbonate powder mixes with resin, gets extruded into sheets, and undergoes calendaring for smooth surfaces. The entire process of how stone paper is made demonstrates why facilities need production line expertise for sustainable manufacturing initiatives.

After base sheet production, assembly line principles take over for converting stone paper into finished products. Workers or automated systems cut sheets to size, apply coatings, and package materials for shipment. Each stage requires different equipment and expertise.

Our smart system integration capabilities help manufacturers combine production and assembly operations efficiently. Sensors track material flow between processing stages. Digital controls adjust speeds across different line sections. This integration ensures smooth transitions, whether you’re transforming raw materials or assembling finished products.

We work with businesses across industries, including lighting, hardware, and industrial machinery. The manufacturing challenges differ, but the core question remains the same: do you need production capabilities, assembly operations, or both? Getting that answer right determines your facility layout, equipment purchases, and workforce requirements.

Conclusion

The difference between a production line and an assembly line comes down to what happens to materials at each stage. Production lines transform raw materials through multiple processes. Assembly lines join pre-made components into finished products. Most modern facilities need both capabilities working together.

Understanding this distinction helps you make better decisions about equipment, facility layout, and workforce planning. Whether you’re setting up a new manufacturing operation or optimizing an existing facility, knowing which type of line you actually need saves time and money.

Smart manufacturing increasingly blurs these traditional lines. Automation and digital integration make it easier to combine production and assembly operations in flexible systems. But the fundamental concepts still matter when you’re planning capacity, training workers, or communicating with suppliers about what your facility actually requires.

FAQ

Production transforms raw materials through processes like cutting, forming, and treating. Assembly joins pre-manufactured components together without changing their fundamental properties.

Yes, most modern manufacturing facilities combine both types. Production lines create components or sub-assemblies, which then move to assembly lines for final product integration.

Not necessarily. Speed depends on product complexity and automation level. Assembly lines can be faster for joining simple components, but production lines with automation can process materials extremely quickly.

Automotive, electronics, appliances, and consumer goods industries rely heavily on assembly lines. Any product made from multiple pre-manufactured parts benefits from assembly line approaches.

Automation makes it easier to integrate both concepts in flexible manufacturing systems. Robots can handle both material processing and component assembly, reducing the traditional separation between production and assembly operations.

References

[1] Library of Congress. “Ford Implements the Moving Assembly Line.” This Month in Business History. https://guides.loc.gov/this-month-in-business-history/October/Ford

[2] Convergix Automation. “7 Key Manufacturing Automation Statistics.” August 2024. https://convergixautomation.com/7-manufacturing-automation-statistics-and-key-takeaways/

[3] Thunderbit. “Automation Statistics 2025: Comprehensive Industry Data and Market Insights.” May 2025. https://thunderbit.com/blog/automation-statistics-industry-data-insights