Converting Machinery

Converting Machinery: High-Speed Solutions for Slitting, Cutting, and Surface Treatment

Converting Equipment and Machinery

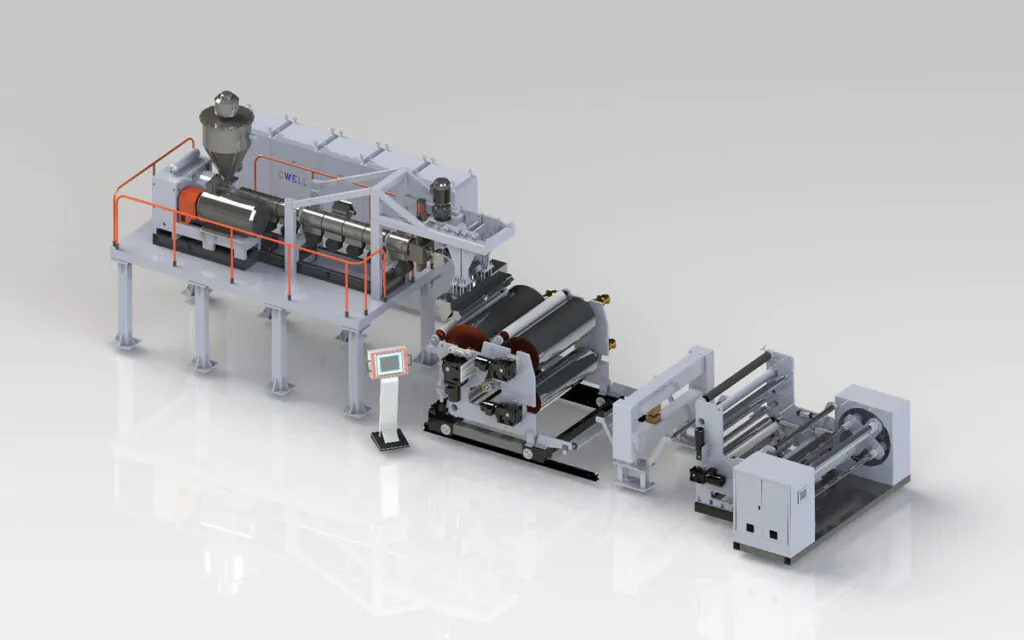

When production demands precision, businesses turn to specialized converting equipment and machinery partners who deliver results. Our Industrial Machinery Solutions provide cutting-edge technology for slitting and rewinding, laminating, and die-cutting across paper, film, and flexible packaging applications. We deliver robust, efficient, and customizable converting machines engineered for the precise demands of modern manufacturing.

What is converting machinery used for? Converting machinery transforms raw materials into finished products through slitting, laminating, coating, and die-cutting processes. Our converting equipment delivers operational speed and accuracy while ensuring superior product quality and reduced material waste—directly impacting your profitability and competitive position.

Unlock Production Potential with Advanced Converting Solutions

Our industrial converting machinery portfolio addresses the demanding requirements of today’s manufacturers. Every production line presents unique challenges, which is why we deliver converting equipment solutions featuring precision engineering, high-speed operation, and advanced servo control flexibility.

How to choose the right converting equipment for my business? Selection criteria include material specifications, production volume requirements, facility constraints, and investment parameters. Our engineers analyze these factors to specify optimal configurations for paper converting machinery in tissue converting, corrugated board converting, and label converting applications, as well as plastic converting machines optimized for film converting and flexible packaging manufacturing—whether you require new converting machines or cost-effective used paper converting machinery for sale.

Innovation and Sustainability: Converting's Future

Automation & Industry 4.0

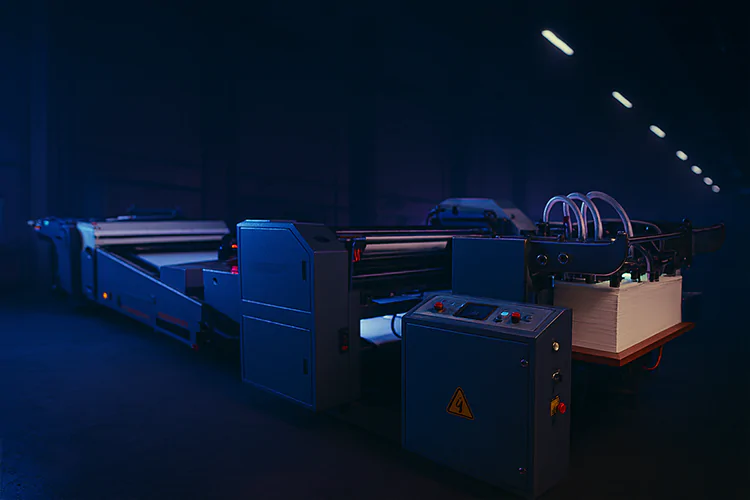

Our machines integrate industrial automation, AI, IoT, and robotics for enhanced efficiency, quality, and flexibility. Predictive maintenance and real-time monitoring minimize downtime while optimizing production output. We deliver data-driven converting solutions providing complete process visibility, driving measurable efficiency gains and increased throughput.

Sustainability Leadership

We prioritize eco-friendly machinery and sustainable processes. Our designs focus on energy efficiency through variable frequency drives, waste reduction technology, and compatibility with biodegradable and recycled materials. We support circular economy principles by developing solutions that reduce resource consumption and streamline operations.

What are the latest innovations in the converting industry? Recent advances include AI-powered quality control systems, IoT-enabled predictive maintenance, servo-driven precision controls, and sustainable coating technologies that reduce environmental impact while improving performance. These converting machines integrate seamlessly with existing production lines while incorporating current converting industry trends, including digital integration and predictive analytics.

Choosing the Right Converting Partner

Selecting converting machines represents a critical production line transformation decision. Whether considering new converting machinery for custom-engineered solutions or exploring used converting machinery for sale for cost-effectiveness, PlentifulChoices guides every step of your equipment selection process.

Critical Selection Factors

Material Compatibility: Machine specification must match your specific material thickness, width, and handling requirements for optimal performance across paper converting, film converting, and nonwoven converting applications.

Production Capacity: Equipment output must align with your volume requirements, from specialized small-batch runs to high-volume flexible packaging manufacturing operations.

Facility Integration: Machine footprint, power requirements, and converting machinery maintenance access must align with your infrastructure capabilities.

Total Cost Analysis: Beyond initial investment, consider consumables, energy consumption, and long-term operational costs. How much does a bag-making machine cost? Investment analysis varies significantly based on specifications, but our team provides detailed ROI calculations for informed decision-making.

Support Infrastructure: Access to expert maintenance, converting machine parts availability, and technical assistance from experienced converting equipment manufacturers ensures operational continuity.

Specialized Converting Equipment Categories

Slitting Machines

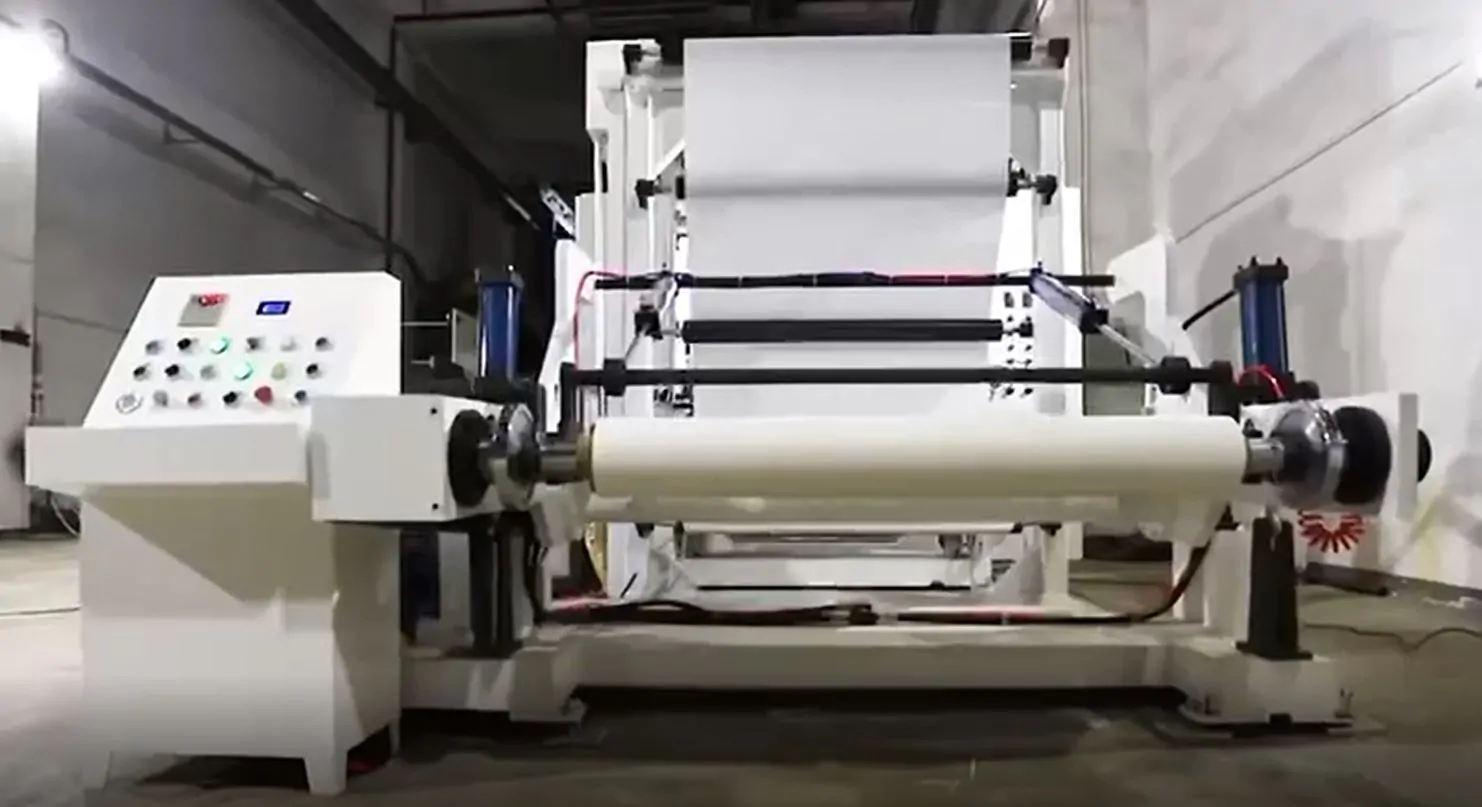

What is a slitter rewinder? Slitter rewinders cut large master rolls into precise, narrower widths while simultaneously rewinding onto new cores. This fundamental converting process prepares materials for subsequent processing or final use applications.

Our high-speed slitter rewinder for flexible packaging delivers exceptional precision and speed, featuring advanced tension control systems and automated core positioning for optimal productivity in adhesive tape production and film converting operations.

Coating Machines for Paper and Film

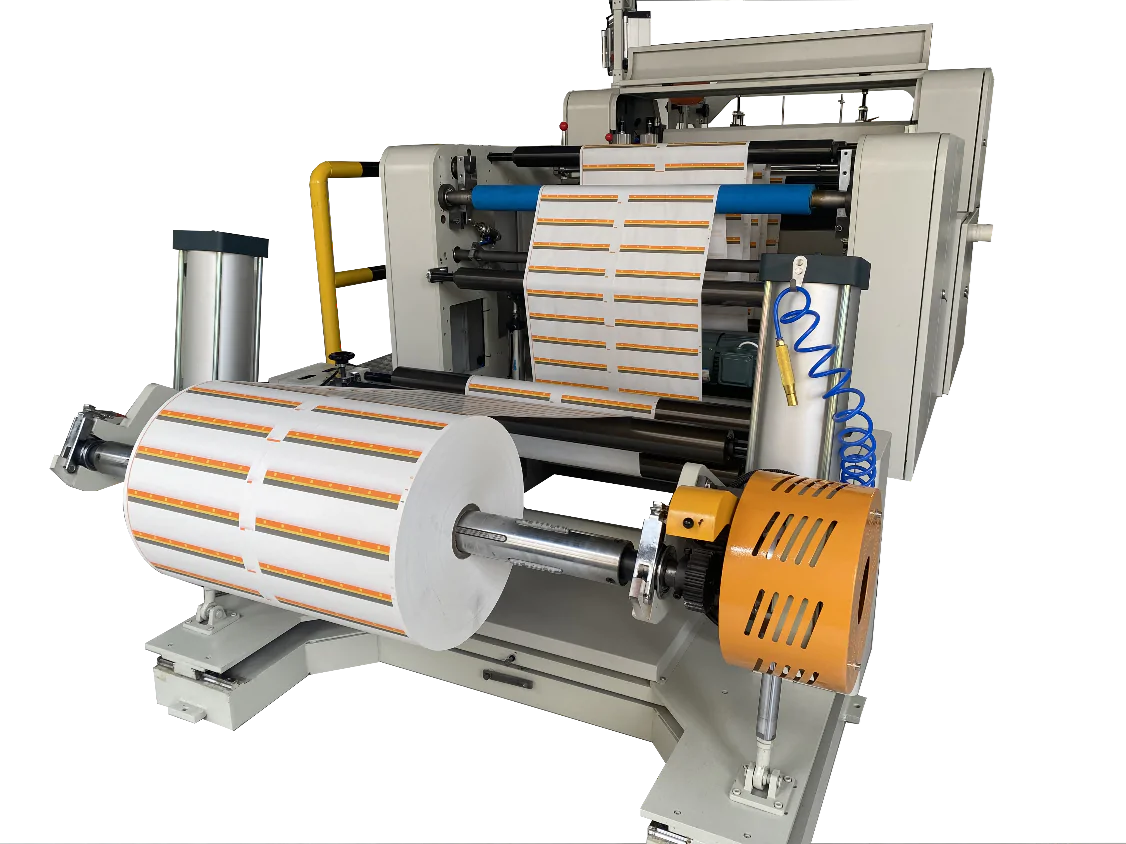

Die-cutting machines and die cutter systems precisely cut and shape materials, including paper, plastic, fabric, and laminates, into specific forms required for packaging components, gaskets, seals, and labels. Our rotary die cutting machine for labels provides superior accuracy and throughput for demanding production environments, representing the best converting machinery technology available.

Cutting Machines

Coating equipment and coater machine systems apply functional and decorative layers to materials, enhancing properties and aesthetic appeal. Whether protective finishes or specialized surfaces, our industrial coaters deliver consistent, high-quality results across all applications.