TL;DR Summary

- Stone paper provides superior water resistance and tear strength compared to traditional paper.

- Environmental impact favors stone paper due to zero tree cutting and reduced water usage.

- Traditional paper remains more cost-effective for most standard printing applications.

- Stone paper excels in outdoor applications, packaging, and specialty printing needs.

- Recycling processes differ significantly between the two materials

What Makes Stone Paper Different from Traditional Paper?

Stone paper consists of 80% calcium carbonate (limestone) and 20% high-density polyethylene resin. This composition creates a synthetic material that mimics paper properties while delivering enhanced performance characteristics.

The stone paper production process vs traditional paper eliminates several environmental concerns. No trees, water, or bleaching chemicals are required during manufacturing, unlike conventional pulp-based methods.

Traditional paper manufacturing involves harvesting wood, chemical pulping, bleaching, and extensive water usage. Each ton of conventional paper requires approximately 24 trees and 7,925 gallons of water.

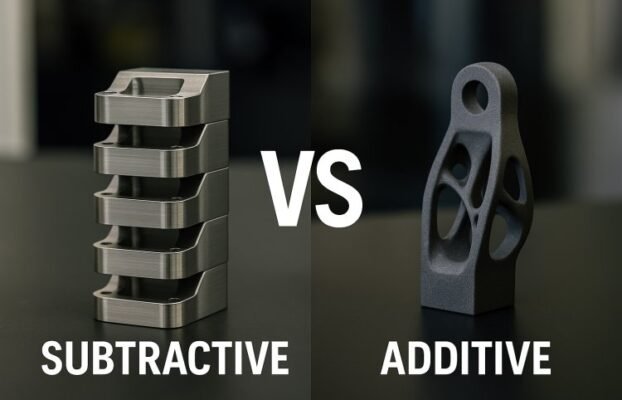

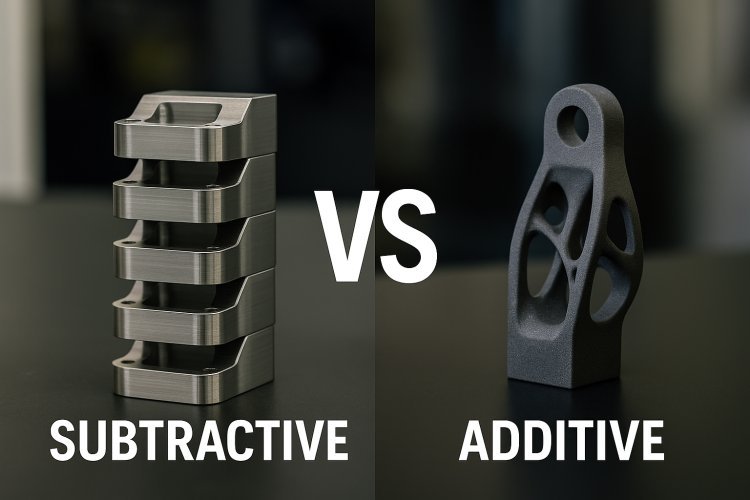

Stone Paper vs Pulp Paper: Manufacturing Processes

Stone paper manufacturing begins with crushing limestone into fine powder, then mixing it with non-toxic resin binders. The mixture passes through calendering machines that create smooth, printable surfaces without chemical treatments.

Traditional pulp paper starts with wood chipping, chemical digestion to separate fibers, washing, bleaching with chlorine compounds, and finally pressing into sheets. This process generates significant wastewater and chemical byproducts. PlentifulChoices specializes in optimizing both manufacturing approaches, helping companies transition between different paper production methods based on their specific requirements.

Environmental Impact: Stone Paper vs Traditional Paper

Stone paper sustainability metrics show significant advantages in several categories. Zero deforestation occurs during production, and no water pollution results from the mineral-based process.

Carbon footprint analysis reveals mixed results. Stone paper eliminates tree-cutting emissions but requires energy-intensive mining operations for limestone extraction.

Environmental impact of stone paper vs traditional paper studies indicate 25-62% lower CO2 emissions during manufacturing compared to virgin paper production. The global paper industry, valued at $344.74 billion in 2024, continues working toward sustainable production methods. Traditional paper manufacturers have reduced GHG emissions by 55.8% since 1972 through improved efficiency and renewable energy adoption. However, traditional paper offers better end-of-life biodegradability in natural environments.

Stone Paper vs Traditional Paper Durability

Stone paper vs traditional paper durability tests demonstrate clear performance differences. Stone paper maintains structural integrity when exposed to moisture, oils, and temperature fluctuations.

Is stone paper waterproof? Yes, it provides complete water resistance, unlike traditional paper that deteriorates rapidly when wet. This makes stone paper ideal for outdoor applications and marine environments.

Tear resistance testing shows stone paper requires 40% more force to rip compared to standard wood pulp alternatives. Traditional paper fibers separate easily along grain lines, while stone paper maintains uniform strength in all directions.

Cost Analysis: Stone Paper vs Regular Paper Price

Stone paper vs regular paper price comparisons reveal significant differences. Stone paper typically costs 2-3 times more than conventional alternatives due to specialized manufacturing equipment and raw material processing.

Traditional paper benefits from established supply chains, mature manufacturing infrastructure, and economies of scale developed over centuries of production.

However, stone paper’s durability reduces replacement frequency in demanding applications. Products like stone paper notebooks vs regular notebooks last longer in harsh conditions, potentially offsetting higher initial costs.

Applications and Use Cases

Stone paper for printing works excellently with offset, digital, and screen printing methods. The smooth surface accepts inks uniformly, producing sharp text and vibrant colors without bleed-through.

Stone paper packaging applications include food service, cosmetics, and the pharmaceutical industries, where moisture resistance prevents product contamination. Traditional paper packaging requires additional protective coatings for similar performance.

Stone paper labels vs paper labels offer superior adhesion and weather resistance. Outdoor signage, marine applications, and industrial labeling benefit from stone paper’s tear resistance and waterproof properties.

Specialized production line setup considerations apply when switching between stone and traditional paper manufacturing, requiring different equipment configurations and quality control processes.

Stone Paper Recycling and End-of-Life Considerations

Stone paper recycling presents unique challenges. The mineral-resin composition cannot be processed through standard paper recycling facilities, requiring specialized separation techniques to recover calcium carbonate.

Traditional paper recycling infrastructure handles wood pulp effectively, with established collection and reprocessing systems achieving 68% recovery rates in developed countries. Paper recycling saves 155 million metric tons of CO2 equivalent emissions annually in the United States alone.

Can you recycle stone paper? Yes, but it requires different processing methods. The calcium carbonate can be recovered and reused in construction materials, while the resin component may be repurposed for plastic applications.

Stone Paper Pros and Cons Summary

Advantages:

- Waterproof and tear-resistant properties

- Zero tree consumption during production

- Smooth printing surface with excellent ink adhesion

- Chemical resistance in harsh environments

- Longer lifespan in demanding applications

Disadvantages:

- Higher production costs compared to traditional alternatives

- Limited recycling infrastructure availability

- Non-biodegradable in natural environments

- Requires specialized disposal methods

- Higher energy consumption during limestone mining

Making the Right Choice for Your Needs

The stone paper vs wood pulp paper decision depends on specific application requirements. Industries requiring moisture resistance, durability, and outdoor performance benefit from stone paper’s superior properties.

Traditional paper remains optimal for standard office printing, books, and applications where biodegradability matters. Cost-sensitive projects typically favor conventional alternatives due to established supply chains.

A professional stone paper line setup requires careful consideration of equipment compatibility, raw material sourcing, and end-product specifications to ensure successful implementation.

Conclusion

Stone paper vs regular paper comparisons reveal distinct advantages for each material type. Stone paper excels in demanding environments requiring water resistance and durability, while traditional paper maintains cost advantages for standard applications.

Environmental considerations present trade-offs between tree preservation and mining impacts. Manufacturing efficiency improvements continue to develop for both materials as technology advances.

The optimal choice depends on balancing performance requirements, environmental priorities, and budget constraints

for specific use cases.

Frequently Asked Questions

Stone paper uses 80% limestone and 20% resin, making it waterproof and tear-resistant. Traditional paper uses wood pulp fibers, making it biodegradable but susceptible to moisture damage.

Stone paper eliminates deforestation and reduces water usage during production, but traditional paper offers better biodegradability. Environmental benefits depend on specific lifecycle factors and disposal methods.

Stone paper manufacturing crushes limestone into powder, mixes it with resin, and presses it into sheets without water or chemicals. Traditional papermaking involves wood pulping, chemical treatments, and water-intensive processing.

Stone paper requires specialized recycling processes to separate limestone and resin components. Standard paper recycling facilities cannot process stone paper, but the materials can be recovered for other applications.

Yes, stone paper typically costs 2-3 times more than traditional paper due to specialized manufacturing and raw material processing requirements.

Stone paper provides waterproof properties, tear resistance, smooth printing surfaces, chemical resistance, and a longer lifespan in harsh conditions compared to traditional alternatives.

Yes, stone paper requires 40% more force to tear than traditional paper and maintains uniform strength in all directions, unlike wood pulp paper, which tears easily along grain lines.